Green practices just make sense for growing number of craft brewers

Making beer can be a green endeavor. Local brewers are proving it.

With a growing richness and evolving complexity of flavor profiles, many craft beer drinkers are often unaware of just how much water is in each glass of beer they drink, let alone the water it takes to clean and sanitize bottles, wash out brewing equipment, and grow crops.

Factor in glass, cardboard, and plastic packaging, transportation, electricity usage and all of a sudden breweries are looking at an awfully large carbon footprint — the environmental and economic impact of which breweries nationwide are beginning to take a long hard look at. Many are reconstructing their business models around more sustainable practices.

In a recent Second Wave Media article, we discussed the use of solar panels by Marshall’s Dark Horse Brewing Company, but energy creation is only one way breweries are attempting to lower their environmental footprint and and make for a more sustainable existence.

“The craft beer industry is now approaching its teenage years. Many breweries are reaching a size where they are beginning to run into issues of how much waste they produce,” says Jarrett Diamond, University of Michigan graduate and co-founder of the Green Brewery Project. “Some of these issues are only happening because the craft beer industry is growing the way it is, and we’re in a stage of growth where the issue of waste needs to be addressed.”

The Green Brewery Project is a not-for-profit consulting firm that works with breweries to “offer creativity in energy and water systems analysis to help craft breweries enhance their sustainability and their bottom line.”

“What we’re finding is that many breweries don’t realize they can afford to be more sustainable. And that they really can’t afford to be unsustainable,” Diamond says. “So we identify how they can lower their carbon footprints. We also help them find funding for it.”

That funding can go towards something as progressive as an onsite waste water treatment facility to something as simple as replacing old bulbs with LED’s or installing a Clean-In-Place system in the brewing tanks. The latter is a mechanical cleaning device that fits inside brewing tanks, spraying and scrubbing them clean with a pre-set amount of water. It replaces the old-school “guy and a hose” technique that uses far more water than necessary.

“It’s like having a mini automatic dishwasher in your tanks,” Diamond says. “They’ve been in place since the 1950’s and it appears to have begun in the dairy and processed food industries and also is widespread in pharmaceuticals and cosmetics industries.”

But sustainability means more than just having an environmental consciousness and helping to protect the resources needed for production. It also means continuing to create high-quality, market-ready products. Because without consumer demand, both environmental stewardship and commercial longevity would be moot points for any business.

“You have to produce a product that is competitive in the market,” says Walker Modic, Sustainability Specialist at Bell’s Brewery Inc. “Sustainability is also about a robust business practice. People tend to attach the word to an environmental ethos and working with good environmental practices and stewardship but they also have to produce a high-quality product.”

Modic’s job is a relatively new one within the brewing industry. Since the spring of 2013 his task has been making certain the brewery’s company-wide ethos of using resources responsibly balances with Bell’s need to produce ever larger quantities of high-quality craft beer.

“When we train people here, I tell them ‘it’s my job to come tinker with your job, but if ever my project impedes your ability to produce a high-quality product, then I’m doing my job wrong,”’ Modic says.

And what’s the best way to make certain Modic’s projects don’t interfere with the jobs of others? Education. Teach all employees not only how to work sustainably, but why doing so is important to the company’s bottom line, to the environment and in some cases, most importantly, their own job security.

“Employee education is key and good water management starts at the employee level,” Diamond says. “That means finding and repairing leaks, not leaving the water on, making sure everyone throughout the company knows that water conservation is a priority. Beyond filtering and re-using waste water, and taking on ambitious, large-scale changes, in many regards the real key to conservation and sustainability lies in the mundane, day-to-day proceedings.”

Not that looking at the big picture is a waste of time. In fact, many brewers see a direct link between the degradation of natural resources and their ability to create a high-end product. In making this connection they are joining forces to raise awareness for and improve the resources needed in beer production.

The Clean Water Pledge, a project founded by the Natural Resource Defense Council and supported by a collection of brewers nationwide, aims to find ways to continue cleaning current water sources while also actively searching for ways to reduce the amount of waste water that is produced during brewing.

Nestled between four of the world’s largest freshwater lakes, Michigan brewers have a unique perspective on how important clean water is both intrinsically as well as commercially. So it should come as no surprise that several area companies, including Arcadia Ales in Battle Creek and Kalamazoo, Arbor Brewing in Ann Arbor, Brewery Vivant and Founders in Grand Rapids, are among those who have taken the clean water pledge and are actively involved in finding ways to remain sustainable.

Breweries are also finding other creative ways to raise both funds and awareness for clean water. For example, in September Bell’s hosted “The Great Lakes Gala,” a charity event that raised money for the Alliance for the Great Lakes, the Michigan League of Conservation Voters, the Kalamazoo Nature Center, and the Michigan Environmental Council.

“The Alliance For the Great Lakes is a particular passion of (Bell’s founder) Larry (Bell). By-in-large we try not mix alcohol with politics, cars, or kids, but the Great Lakes are the largest un-salinated bodies of water in the world, and if we’re not careful, well, you don’t want to realize how valuable it is until it’s gone,” Modic says.

As Bell’s fights for clean water in the Great Lakes, it also takes very seriously its job to protect and clean the water closer to home as well. That’s why the brewery is currently constructing a pretreatment facility that will process many of the byproducts from brewing–waste yeast, spent grain and other particulate matter–and create reusable energy from what would otherwise go to the city’s waste water treatment plant.

“We’ll start treating waste water with an anaerobic system that will allow us to remove around 80 to 85 percent of biological waste and turn it into methane. Come December we’re hoping to produce our first renewable kilowatt hour,” Modic says.

Over the course of its three decade existence Bell’s has taken many steps towards equipping its brewery for a sustainable future, but it has also looked outward in attempting to lessen its footprint as well, including:

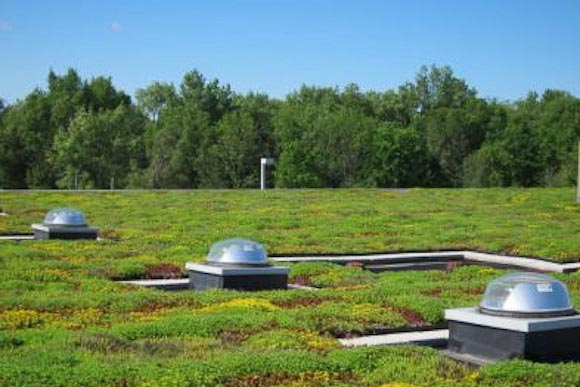

• the installment of a modular, extensive sedum green roof on its conditioning warehouse to increase insulation efficiency,

• a 16-ton closed loop geothermal field that provides heat to the office staff, and

• an experiment with a no-till barley farm in Shepard that includes data Bell’s collects and shares with other area farmers.

For many industries the tightrope between commercial growth and environmental best practices is not always easy to traverse, but in a field such as craft brewing that relies so heavily on fresh, seasonal ingredients and on the ability to find readily available fresh water, focusing attention on preserving resources leads, more often than not, to financial success if their final product meets with approval from consumers.

Modic sums up the balance of sustainability vs. quality and production this way: “We plan to make beer for a long time, and in order to do so we need a viable stream of high quality resources such as water, barley, and hops and our behavior in the environmental and social sectors are going to have an effect on the availability of those products.”

Jeremy Martin is the craft brew writer for Southwest Michigan’s Second Wave.

Photos courtesy Bell’s Brewery Inc.